MULTI STAGES HYDRATOR SERIES

Hydrated lime is the second most important product of the lime industry and modern industrial applications developed in the 20th century require many different qualities of lime, to be manufactured under strictly controlled conditions. In particular relatively new industrial uses, such as FGD, have required new product characteristics, from enhanced average fineness, to higher surface area and pore volume.

This has led to the needs to evolve and partly redesign hydration equipment and their ancillary components in order to meet the product quality demands on the one hand, and the emissions standards on the other.

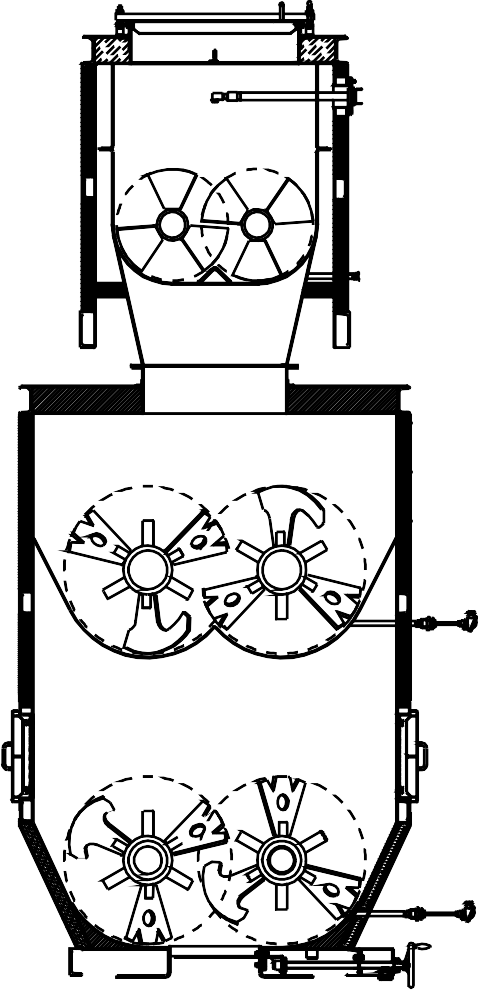

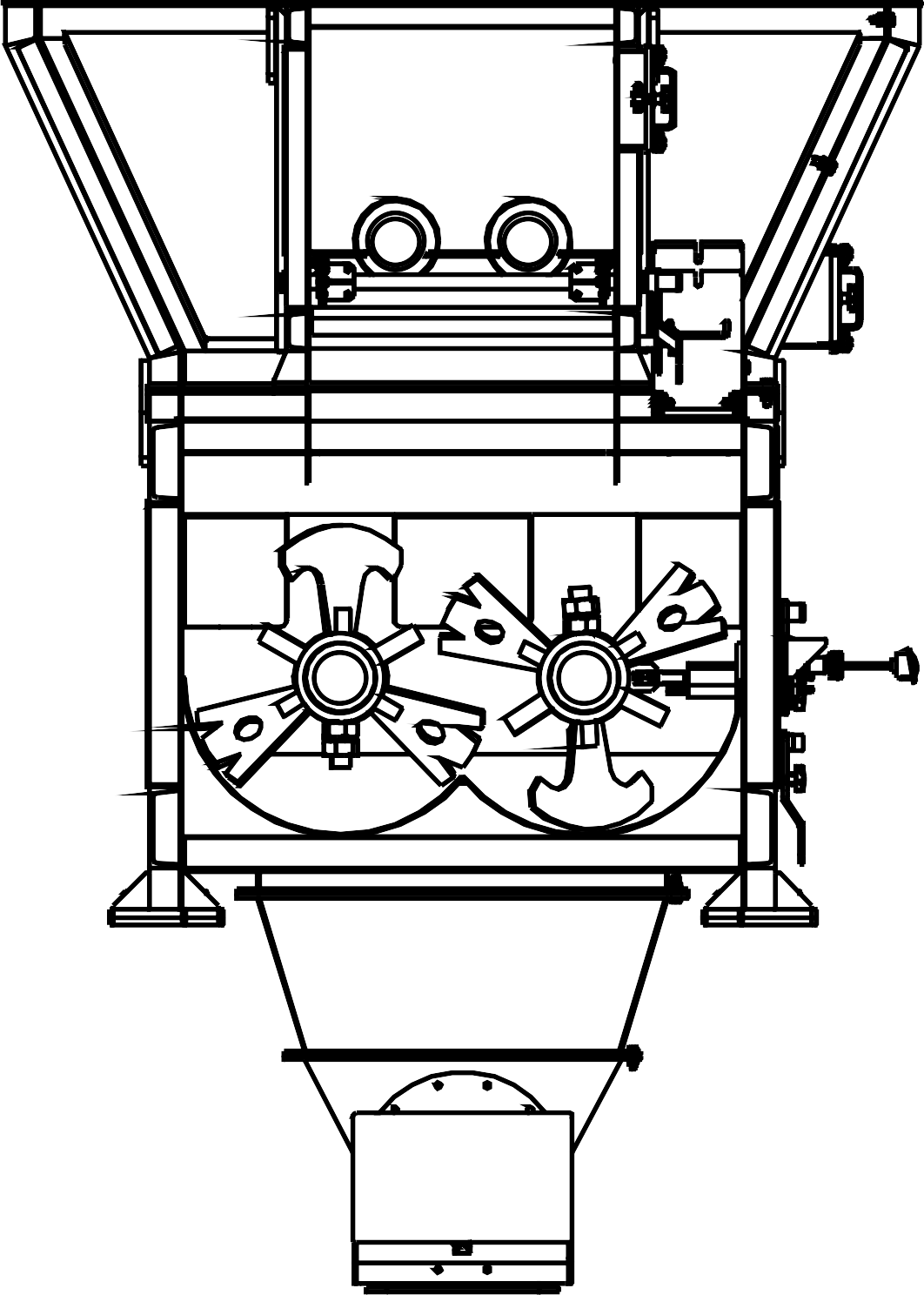

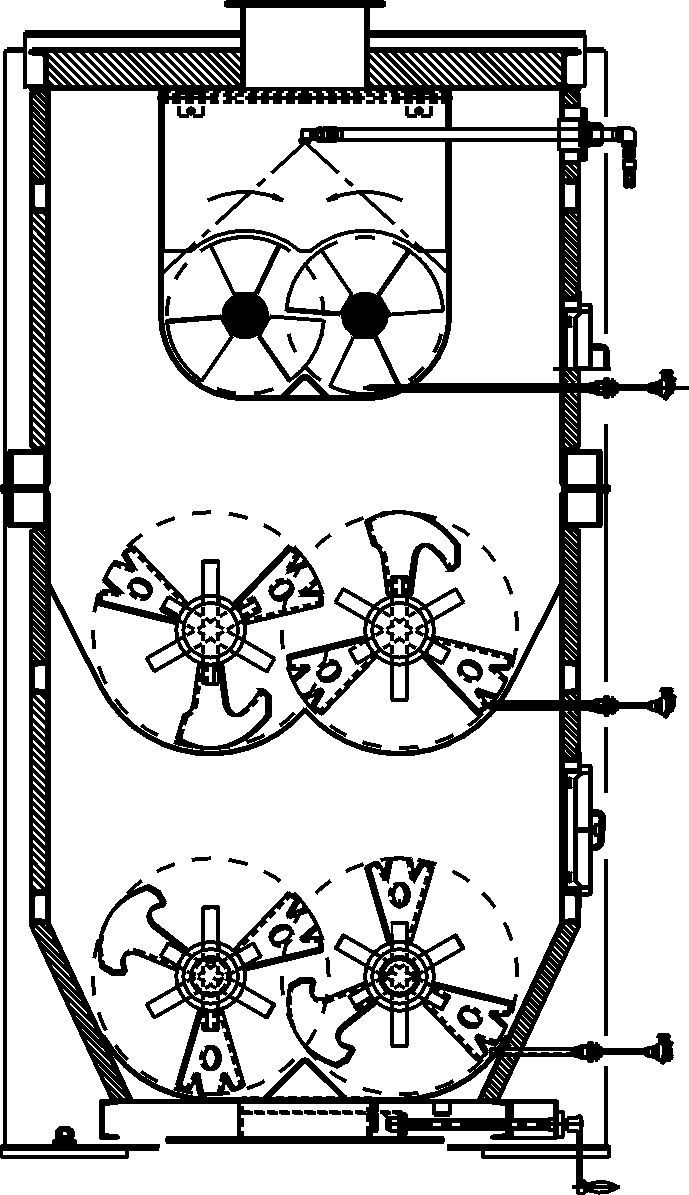

Hydrator

Cim-HYDRAX-4G MAX

for enhanced fineness of raw hydrate

Hydrator

Cim-HYDRAX-FGD

for flue gas desulphurization applications

Special applications ![]()

Hydrator

Cim-HYDRAX-4G

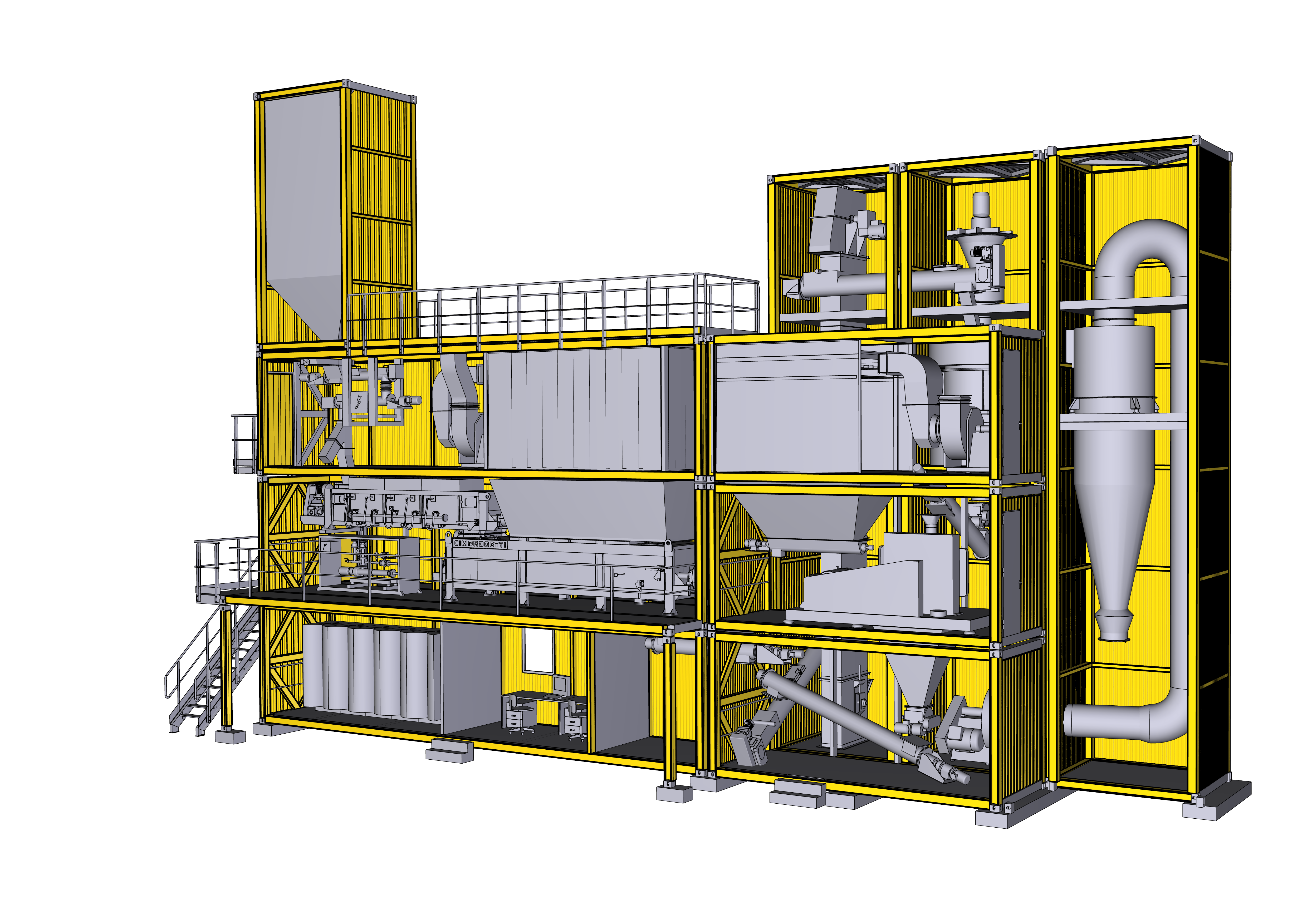

Cim-Hydrax-Compact® ![]()

A complete and autonomous industrial hydration plant, specially designed to be as small and compact as possible by eliminating unnecessary auxiliary machines and spaces, thus greatly reducing the CAPEX and preserving the contractual performance of the Hydrax.

The Cim-Hydrax-Compact® is available in different configurations to meet the maximum flexibility, reduce maintenance and running costs, while obtaining excellent qualities and outputs.

In order to get more from a smaller footprint, our Customer Care Service is able to advise the most adequate technical options according to laboratory tests and to the retrofitting space.

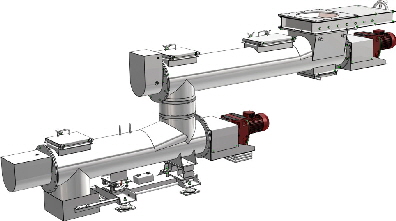

Pilot hydrator ![]()

An accurate scale down of the industrial machine for an exceptionally wide range of operating conditions.

Very effective testing campaignes at clients plants sites are possible.

The results of the tests are effectively used for the design and supply of the industrial scale hydrator which is best matching the client objectives.

Technical features

- production: up to 130 kg/h

- dimensions: L3800x660xH3850 mm

(including feeding & discharge screw conveyor and bag filter) - electric board dim.: 800x600x2100 mm

- installed power: 5 kW

- total weight: 1600 kg (including electric board)

Client should provide a quicklime feeding hopper above screw conveyor and a collection system of hydrated lime (e.g. a big bag), the electric power connection to the board and water connection to hydrator.

A range of specialized equipment has also been developed for the hydration process, namely:

Cim-Digidoser

the digital weighing feeder

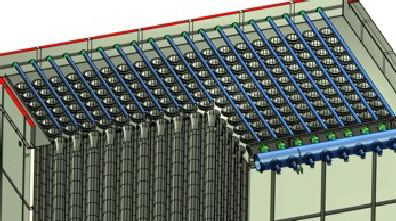

Cim-Zeropoll

the dedicated bag house filter

Cim-Microsep

high efficiency separator

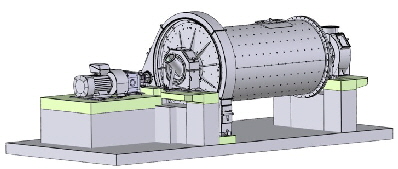

Tubular & vertical mills

Hydration ancillary equipment ![]()