ABC process![]()

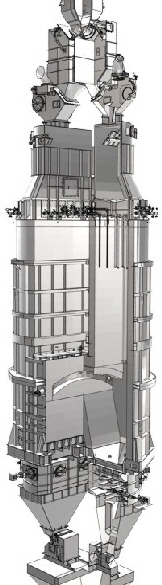

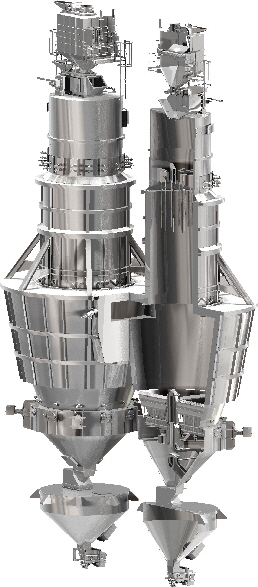

ABC (Advance Burning Concept) is the Cimprogetti vertical single shaft kiln with counter current flow arrangement and is the latest in the evolution of compact design.

Thanks to its particular firing system, the ABC kiln can produce medium-high to low-reactivity lime with an optimal use of diverse limestone sizes and a variety of fuels.

The ABC kiln features a cylindrical steel shell and is internally lined with standard-size refractory bricks. The limestone is continuously fed into the sealed loading/distributing device placed on the top of the kiln. Burning takes place in the lower/middle part of the kiln, through a number of burners distributed in several rows around the kiln shell to ensure homogeneous and consistent distribution of the heat over the entire kiln cross section. The lower section of the kiln is equipped with a lime discharge and a lime cooling section by means of air which is introduced from the bottom of the discharge table.

ABC

single shaft cross section

TWIN SHAFT REGENERATIVE PROCESS

- Natural gas

- Lean gas: COG, BF, Corex gas, mixed gas, Syngas...

TSR lime kilns can be fired with:

TSR KILNS DESIGNED TO MEET CUSTOMERS’ PRESENT AND FUTURE REQUIREMENTS ...

- LDO

- MDO

- HFO

- Waste oils ...

- Petcoke

- Anthracite

- Lignite

- Coal

- Saw dust

Cim-ReVerSy TSR models![]()

Twin-D®

direct cross over channel

Flex ReVerSy®

direct cross over channel

Vanguard®

radial cross over channel

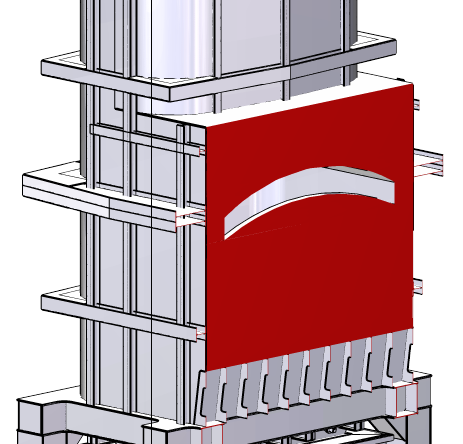

Cim-ReVerSy TSR process![]()

The Twin Shaft Regenerative (TSR) kiln family consists of two main groups:

- Direct Crossover featuring a single channel placed between the shafts,

- Radial Crossover featuring circular channels around the shafts which are then connected in the central part.

The TSR-Kilns series utilizes the regenerative process for lime calcination. There are two distinguishing characteristics for the TSR-Kilns:

- the parallel flow of hot gases and stone in the burning zone, which allows a mild burning of the limestone without over-burning, and

- the regenerative preheating of all combustion air, using the limestone contained in the preheating zone of the kiln (in the non-burning shaft) as a heat accumulator.

The TSR kilns currently represent the best option for high- and medium-reactivity lime production in terms of:

- lower fuel consumption,

- lower maintenance costs,

- lower emission rates,

- higher quality lime.

DIRECT CROSSOVER CHANNEL

RADIAL CROSSOVER CHANNEL

LIME KILNS TECHNOLOGY

Experience and a well proven design are the secrets for a successful lime burning project as several factors influence the choice of lime kiln technology:

- quality of the raw materials,

- fuel characteristics,

- specifications of the finished product.

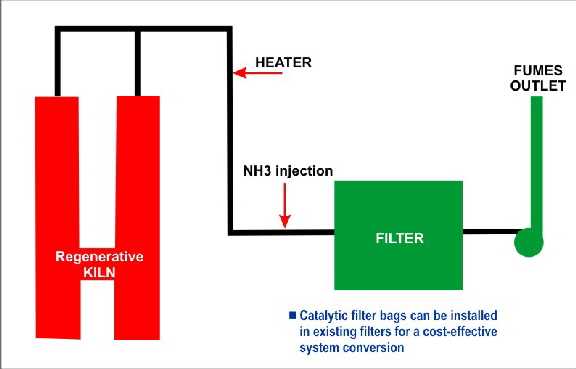

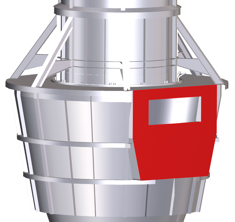

TurNOx® integrated device![]()

Cimprogetti has selected an innovative SCR process for Parallel Flow Regenerative (PFR) kilns with the specific aim of reducing NOx content in flue gases.

Placed downstream of the kiln, the TurNOx® device modulates parameters without affecting the calcination process in the kiln.

The TurNOx® device complies with the main directives regulating emissions into the atmosphere, in particular, the Best Available Techniques.