LIMESTONE, A RESOURCE BY TRADITION

Bergamo is a region with a long history and expertise in the production of lime, cement and ground carbonate.

Numerous mineral deposits are quarried to produce the most important raw materials used in construction and in road network, but also in many other industrial sectors.

The extraction and processing of sand, gravel, stone and lime is not only the functional activity of the companies operating in this sector, but it forms the basis of the development of the entire local community.

The soil and subsoil of our mountains and plains are indispensable resources. They are a legacy of age-old geological history, which has led to the current morphology. The phenomenon of transformation has created a variety of rocks of very different mineralogical composition, quality and physical-mechanical characteristics, which determine their usefulness.

It is a natural resource of great value, which has led to the establishment of the most developed mining industries. A modern production reality, which has invested in technology and human resources.

With 9.7 billion euro of value added (and 156 thousand employees), Bergamo is the second most important industrial province in Europe. (2015 Data from Confindustria ![]() )

)

Workers in a quarry in the

Province of Bergamo

ANCIENT PROCESS FOR THE PRODUCTION OF LIME

The use of lime undoubtedly dates back to prehistoric times, although this material appears to have been more frequently used in the Bronze Age.

The discovery of lime by prehistoric man was probably similar, although not quite as easy, as the discovery of terra cotta. By digging a fireplace in the calcareous soil, prehistoric man noticed that the stone which had been in contact with the fire, after cooling, became dust. This formed a plastic paste when combined with water, which then lost its plasticity and became a rigid material. This was the first stone.

While terra cotta is known to have been widely used by all the historical civilizations, our knowledge of lime is limited to particular civilizations only.

In Rome the “Calcis Cottores” (Lime burners) guild had already designed the shape and function of the lime kiln, which they called “fornax calcaria”. For substantial improvements, we must wait until the second half of the eighteenth century, when Lavoisier established chemistry as a true science that enabled the rational interpretation of the chemical phenomena that governs the manufacture of limes, their use and their behavior.

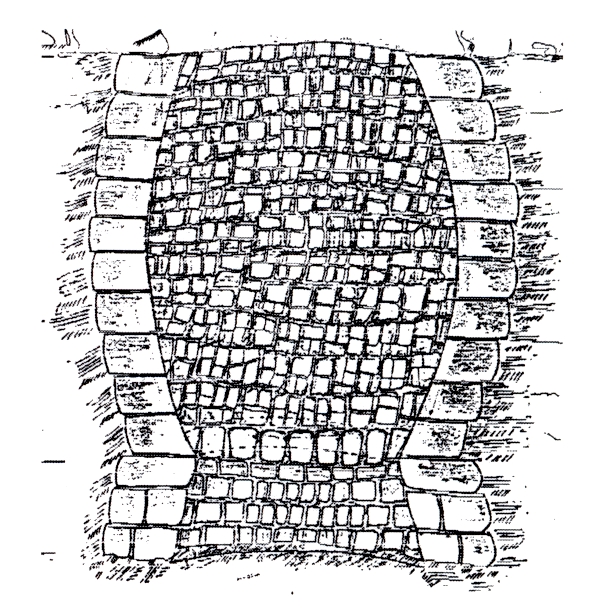

The Bergamo province, where Cimprogetti was founded at the end of the sixties, has an abundance of mountains and forests and a long tradition in lime production. In a manuscript of 1781, there are 38 references to “calchere” (lime kilns). The old lime kiln of the time was composed of two parts: the first one totally embedded underground was used as burner; the second, stacked on top of the first with a slightly larger diameter, was where the limestone was loaded and the actual burning process was attained.

Calchera

Post medieval model of a lime kiln

found in the Province of Bergamo