LIME ENGINEERING

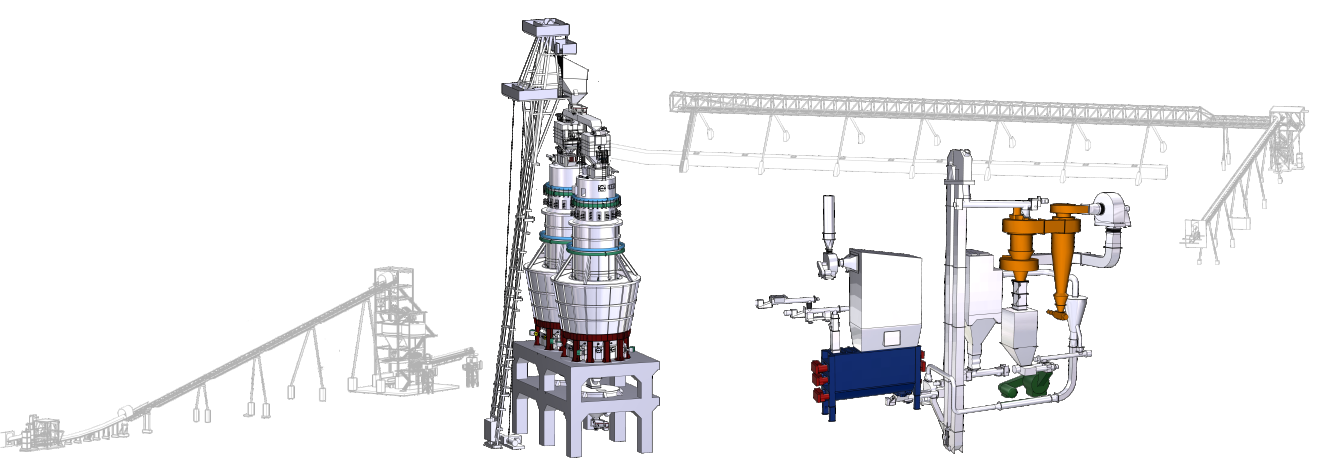

Cimprogetti can process all phases of a lime project, from the feasibility study to commissioning of the plant on the basis of the end-user’s needs and requirements, in order to guarantee performing, reliable and user-friendly plants. Thanks to the advanced technologies available, our experienced team can develop a tailor-made solution for you.

The scope of supply is diversified according to essential guidelines that constitute our core business:

- ENGINEERING - provision of basic-detailed and tailor-made engineering;

- KEY COMPONENTS - supply of essential components;

- TECHNICAL ASSISTANCE - provision of technical supervision;

- SPARE PARTS - supply of spare parts; thanks to the ERP system (Enterprise Resource Planning), spare parts are quickly identified and delivered;

- AFTERMARKET SERVICES - our aim is to be the customer’s point of reference for the resolution of aftersales issues through an integrated supply-chain management system. As global supplier of first-class technology, and thanks to the company's high level of engineering expertise, Cimprogetti is able to solve problems and assist the customer in the most effective way possible.

- EPCm (Engineering, Procurement, Construction Management) - Cimprogetti acts as technology provider leveraging the partnership of companies specialized in construction.

The ultimate Industry Revolution 4.0 in Cimprogetti ![]()

The most recent activity of Cimprogetti decisively towards the future is the application of a number of new technologies, which may create new characterization of industrial processes.

The company is increasingly preparing for the adoption of these technologies that will lead, in the future, to a radical change in the design and production reality.

We remember the CYBER PHYSICAL SYSTEM and INTERNET OF THINGS (IOT), each with its own "intelligence" that interacts dynamically with the outside world and the production systems.

"VIRTUAL REALITY" and "AUGMENTED REALITY", technologies that are changing our approach and relationship with the outside world.

ADVANCED MATERIALS, NANOTECHNOLOGY, and CLOUD CYBER SECURITY, ANALYTICS and BIG DATA make up the industry's new frontier of goods and services and the advanced scope of work of Cimprogetti’s planning activities.

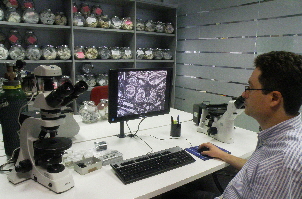

All the plant configurations and technological choices for each project are supported by the analysis and testing of raw materials, finished products and fuels at out in our Technological Innovation LAB, in order to determine the equipment and plant specifications and define the applicable performance parameters for the contract.

Cimprogetti's technological laboratory utilizes modern equipment, including transmitted and reflected light microscopes for petrographic-metallographic examinations, thermogravimetric muffle furnaces for TG-DTG analyses, atomic absorption (AAS) and X-ray fluorescence (XRF) spectrometers for the chemical analysis, a desktop X-ray powder diffractometer (XRPD) for the mineralogical analysis, a laser diffractometer for the particle-size analysis, and, finally, a gas sorptometer for the specific surface area analysis with the BET method.

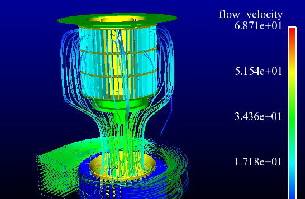

Process Engineering is vital for any industrial plant development. Its broad scope ranges from site visits or surveys and discussing issues with operators, to long-term project development. Our Process engineers design and optimize chemical processes, advise on process safety issues, analyze and interpret laboratory and plant data and, generally speaking, provide technical support to customers with the aim to ensure the technical integrity of equipments and plants.

Mathematical simulation of key plant sections is developed in collaboration with renowned European and Italian universities, to validate innovative solutions which are then adopted in the design of industrial-scale plants.

The Lab forms part of our design department and is equipped with state-of-the-art 3D CAD and CAE workstations to support all the engineering phases of a project.

The ultimate in Lab. ![]()